.png)

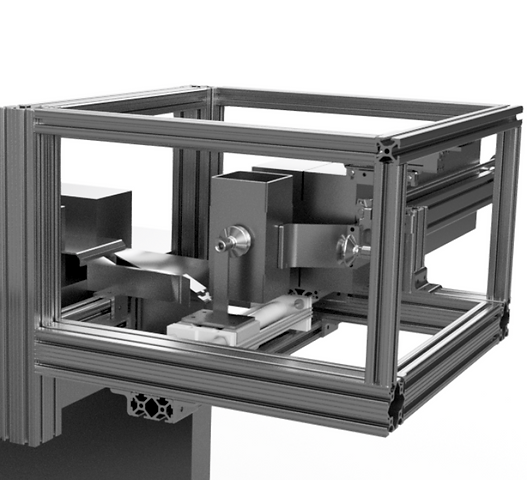

Custom Automation, Robotics, and Machine Design for Unique Manufacturing Challenges

Tired of slow, manual processes that limit your production?

That's where we come in.

We help manufacturers in Utah and the surrounding areas automate bottlenecks, eliminate repetitive tasks, and streamline production with custom-designed machines and systems — no oversized solutions, no overkill, just what works.

Off-the-shelf equipment often doesn’t fit neatly into existing processes and comes with a high price tag that's hard to justify. We design, modify, and integrate both new and legacy machinery to work together seamlessly. Whether you're building something from the ground up or adapting what you already have, we create reliable solutions that fit your operations — and your budget.

Our Specialties

-

Custom Machine & Workstation Design

Tailored equipment built around your exact process needs. -

Robotic Integration

Integration of 6-axis, SCARA, and collaborative robots for pick & place, inspection, and light assembly. -

PLC, HMI & Control Systems

Programming, interface design, and complete control panel builds. -

Specialized Tooling & Fixtures

Custom jigs and end-of-arm tools for precision and repeatability. -

Equipment Retrofits & Upgrades

Modernize existing machines with updated automation and controls.

Perfect for:

Manufacturers and fabricators who need precise, cost-effective automation — built to match their workflow, not force-fit into a generic system.

Why Choose Us?

-

Custom Machine & Workstation Design

Purpose-built equipment tailored to your process — from initial concept to finished system. -

Robotic Integration

Seamless integration of 6-axis, SCARA, and collaborative robots for pick & place, inspection, light assembly, and more. -

PLC & HMI Programming + Industrial Controls

Complete control system design, from custom PLC logic and HMI interfaces to full panel builds. -

Specialized Tooling & Fixtures

Custom jigs, end-of-arm tooling, and precision fixtures engineered to maximize consistency and efficiency. -

Equipment Retrofitting & Upgrades

Modernize legacy equipment with updated controls, automation, or mechanical improvements — no need to start from scratch.

.jpg)

Common Problems We Solve

-

“We’ve got an operator doing the same motion all day — can this be automated with a simple mechanism or small robot?”

-

“We need a machine that does a very specific task — but nothing off-the-shelf will be a perfect fit for our process.”

-

“We’re manually sorting and placing parts on a conveyor — we want a robotic cell to handle this without slowing down production.”

-

“We need a custom end-of-arm tool for our robot that can handle delicate or oddly shaped parts without damage.”

-

“Our current machine still works, but the controls are outdated and hard to troubleshoot — can you upgrade the PLC and HMI?”